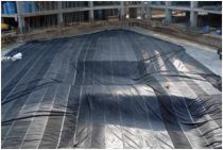

EPDM membranes are laid as strips, side by side, on the smooth lean concrete surface, prepared beforehand, in the foundation of the building. Then, the membrane binis, with a width of 4 cm, to each other, are welded to the existing thermoplastic strips present on the membrane by applying hot air and pressure. Pieces produced from EPDM rubber are used for details like internal and external corners.

EPDM membranes are laid as strips, side by side, on the smooth lean concrete surface, prepared beforehand, in the foundation of the building. Then, the membrane binis, with a width of 4 cm, to each other, are welded to the existing thermoplastic strips present on the membrane by applying hot air and pressure. Pieces produced from EPDM rubber are used for details like internal and external corners.

The thermic welding sewing completed is checked with sewing control tester. If required, welding safety mastic is used in the bini places. The application area after the controls made is subjected to water test by filling water for the final control. After the water test completed with success, the top of the EPDM membrane is covered with 150-300 g/m2 geotextile felt. Then, the surface of the membranes are protected with the protection concrete with a thickness of 10 cm and made ready for raft foundation.